191.32.2240.990.41.1502 Standard 5 Slewing Ring Bearings

| Brand Name: | Standard 5 |

| Model Number: | 191.32.2240.990.41.1502 |

| Bearing number: | S7000 CE/P4A |

| Size (mm): | 26x10x8 |

| Bore Diameter (mm): | 26 |

| Outer Diameter (mm): | 10 |

| Width (mm): | 8 |

| d: | 10 mm |

| D: | 26 mm |

| B: | 8 mm |

Product Details

| Bearing number | S7000 CE/P4A |

| Size (mm) | 26x10x8 |

| Bore Diameter (mm) | 26 |

| Outer Diameter (mm) | 10 |

| Width (mm) | 8 |

| d | 10 mm |

| D | 26 mm |

| B | 8 mm |

| d1 | 15.6 mm |

| d2 | 14.5 mm |

| D2 | 22.35 mm |

| r1,2 - min. | 0.3 mm |

| r3,4 - min. | 0.3 mm |

| a | 6.5 mm |

| da - min. | 12 mm |

| da - max. | 15.2 mm |

| db - min. | 12 mm |

| db - max. | 14.1 mm |

| Da - max. | 24 mm |

| Db - max. | 23.6 mm |

| ra - max. | 0.3 mm |

| rb - max. | 0.3 mm |

| Basic dynamic load rating - C | 3 kN |

| Basic static load rating - C0 | 1.2 kN |

| Fatigue load limit - Pu | 0.05 kN |

| Limiting speed for grease lubrication | 90000 r/min |

| Ball - Dw | 3.969 mm |

| Ball - z | 11 |

| Calculation factor - f0 | 7.1 |

| Preload class A - GA | 15 N |

| Preload class B - GB | 48 N |

| Preload class C - GC | 95 N |

| Calculation factor - f | 1 |

| Calculation factor - f2A | 1 |

| Calculation factor - f2B | 1.03 |

| Calculation factor - f2C | 1.05 |

| Calculation factor - fHC | 1 |

| Preload class A | 12 N/micron |

| Preload class B | 19 N/micron |

| Preload class C | 26 N/micron |

| r1,2 min. | 0.3 mm |

| r3,4 min. | 0.3 mm |

| da min. | 12 mm |

| da max. | 15.2 mm |

| db min. | 12 mm |

| db max. | 14.1 mm |

| Da max. | 24 mm |

| Db max. | 23.6 mm |

| ra max. | 0.3 mm |

| rb max. | 0.3 mm |

| Basic dynamic load rating C | 3.02 kN |

| Basic static load rating C0 | 1.18 kN |

| Fatigue load limit Pu | 0.05 kN |

| Attainable speed for grease lubrication | 90000 r/min |

| Ball diameter Dw | 3.969 mm |

| Number of balls z | 11 |

| Preload class A GA | 15 N |

| Static axial stiffness, preload class A | 12 N/µm |

| Preload class B GB | 48 N |

| Static axial stiffness, preload class B | 19 N/µm |

| Preload class C GC | 95 N |

| Static axial stiffness, preload class C | 26 N/µm |

| Calculation factor f | 1.03 |

| Calculation factor f1 | 1 |

| Calculation factor f2A | 1 |

| Calculation factor f2B | 1.03 |

| Calculation factor f2C | 1.05 |

| Calculation factor fHC | 1 |

| Calculation factor f0 | 7.1 |

| Mass bearing | 0.019 kg |

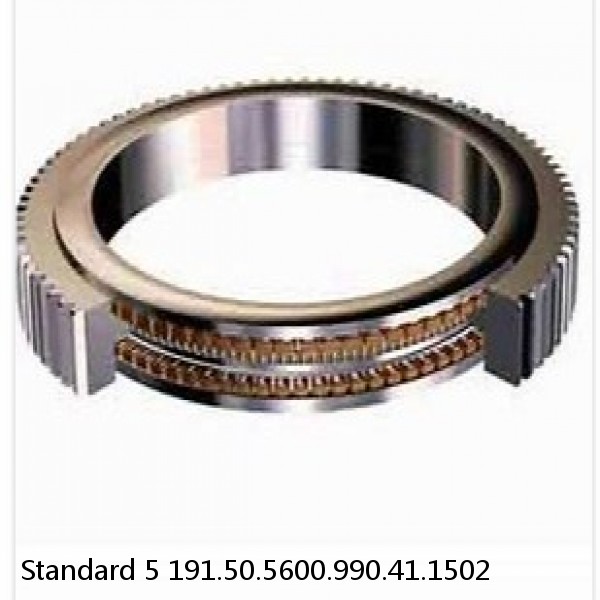

121.45.5600.990.41.1502 Standard 5 Slewing Ring Bearings

121.45.5600.990.41.1502 Standard 5 Slewing Ring Bearings 121.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings

121.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings 191.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings

191.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings 192.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings

192.50.5600.990.41.1502 Standard 5 Slewing Ring Bearings 121.40.5300.990.41.1502 Standard 5 Slewing Ring Bearings

121.40.5300.990.41.1502 Standard 5 Slewing Ring Bearings 121.45.5300.990.41.1502 Standard 5 Slewing Ring Bearings

121.45.5300.990.41.1502 Standard 5 Slewing Ring Bearings